BioNTech

Support for SARS-CoV-2 vaccine production

The project at BioNTech is of high urgency due to the Corona Pandemic. Despite the associated enormous pressure, the quality of all work and production processes must not suffer as a result.

Consistent support from our experts makes sense both in the run-up to an intended project and during implementation. This gives you the information you need to make important decisions.

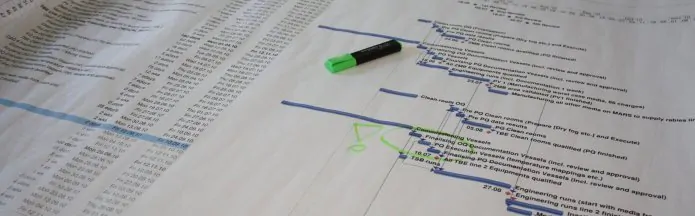

No project without changes. However, changes must never be implemented “on demand”. Our specially developed change management system has already proven itself in several projects as user-friendly and uncomplicated. In this way, you always have control and an overview of all requested and approved changes and their impact on costs and deadlines.

Risk and Opportunity Management

Being able to use project management software is not enough for professional risk management. It takes experience to correctly assess the probability of risks occurring and to derive appropriate buffer times or budgets from this. In cooperation with Behrens project management, you will find out in advance which events can affect your schedule or significantly increase your costs. So you are prepared for many eventualities.

However, projects not only harbor risks, but also opportunities. Evaluating these and monitoring their occurrence is also part of our expertise.