Case study project coordination: Who brings structure to the workflow of a project?

Project coordination is always appropriate when interfaces arise between different areas of a project.

Communication is the key to the success of a project, and communication between the interfaces of different project areas must be ensured.

At this point, it is a good idea to appoint project coordinators to ensure that the interfaces concerned are compatible with each other. Coordinations and changes in structures must be passed on to all affected interfaces so that everyone knows what has changed an

Action required:

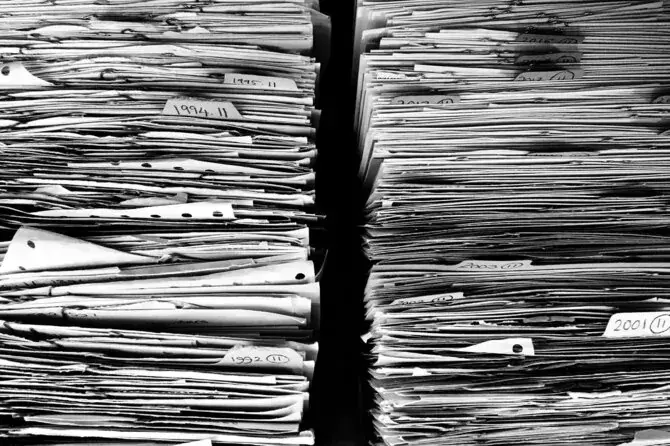

A procurement plan was already available in the customer's project, containing all orders that had been placed and those that were expected (planned but not yet placed). This provided a good overview of all the procurements and orders relevant to the project. project relevant procurements and purchase orders.

Quotations, delivery bills, etc. were stored centrally and accessible to all project participants.

Despite the existing procurement plan, it was sometimes difficult to track when an order went out to the supplier, whether an order confirmation had already been received, whether the order had already arrived, where it was stored, and whether it had already been removed from storage and brought to the construction site.

and brought to the construction site. A solution was needed that would bundle all of this information so that project participants no longer had to sift through various lists and programs looking for the status of the order and other relevant information.

Project coordination by Behrens Projektmanagement:

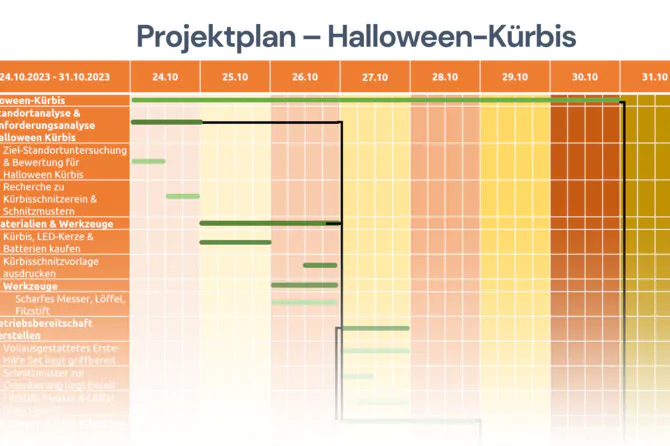

The Procurement Plan has undergone a restructuring. Information that was not relevant was removed. New information was added instead. For example, it was now possible to access the corresponding offer directly from the table, as it was linked directly there. Also, the specific date of the order has been added (before, only the date when the order process was initiated was visible). Likewise, one could directly access the order confirmation, since this was also directly linked - in addition, the corresponding delivery date was entered, in order to be able to act better/faster based on this in case of delivery delays or exceeded delivery dates.

Information concerning received deliveries has also been added. Thus, it was now also possible to see from the procurement plan that the delivery (if this was the case) was delivered and in which warehouse it is located on which pallet. If something was removed from the warehouse and brought to the construction site, this was also noted.

So now you had all the relevant information right at your fingertips in one plan, and you didn't have to sift through different programs using quote numbers or order numbers, but had everything at your fingertips at a glance, one click. Orders can now be tracked better and delays can be responded to faster/better. can be reacted to faster/better.

Resume:

By restructuring the procurement plan, the ordering process or tracking process was significantly optimized. This shows that a new perspective often produces new opportunities. Sometimes it doesn't take much at all to improve processes, it's enough to reorganize the existing information. This is exactly what Behrens Projektmanagement GmbH did at the done at this point.